Select the Machining Process Which Gives Best Surface Finish

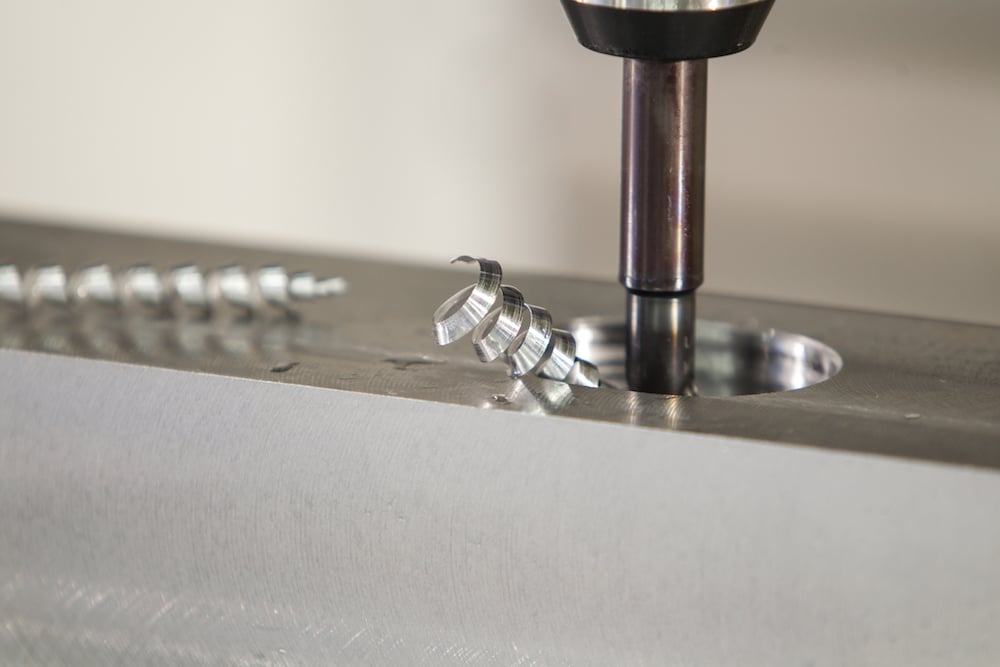

Surface texture is included within the scope of surface integrity. The process of metal machining This is an overview of the most common processes.

Why Use A Surface Finish Chart Metal Surface Finish

Lapping Lapping is regarded as the oldest method of obtaining a fine finish.

. This purely depends on the material you use and end function of the component su. Knowing what manufacturing process can produce surface finishes that desired on a surface can be an added advantage while making the designs. Anodizing Finish.

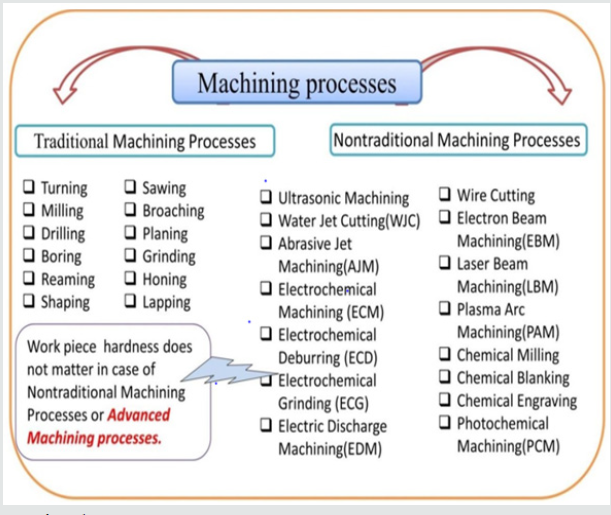

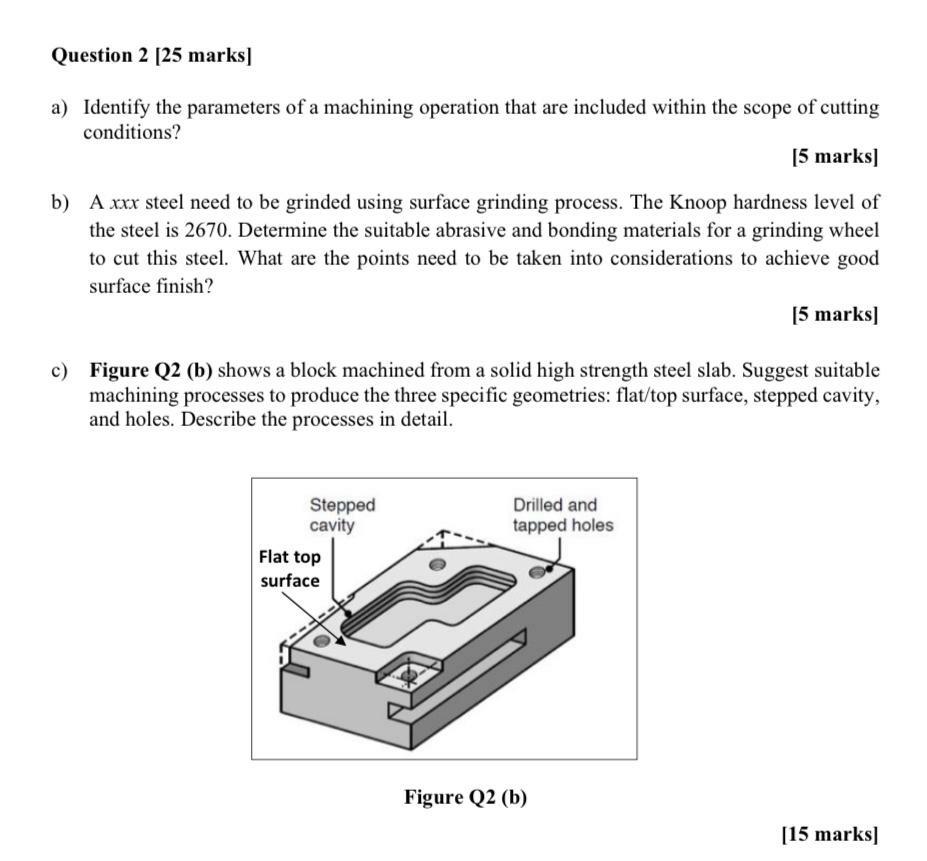

Which process gives best surface finish. In the following videos we will focus mostly on. Such processes can be broadly classified as conventional machining processes turning threading facing drilling boring shaping planing milling grooving reaming etc abrasive cutting processes grinding lapping honing polishing superfinishing etc micro.

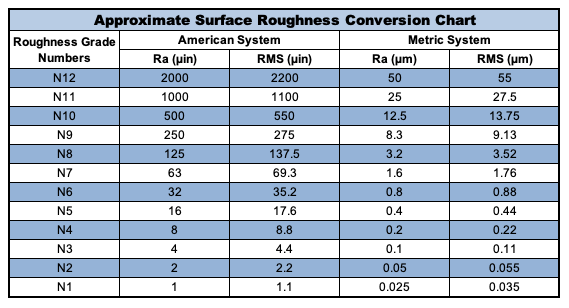

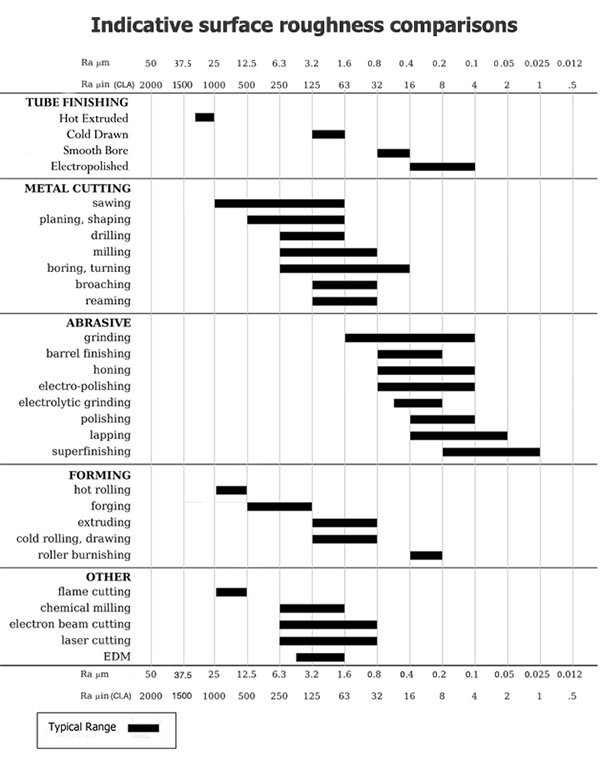

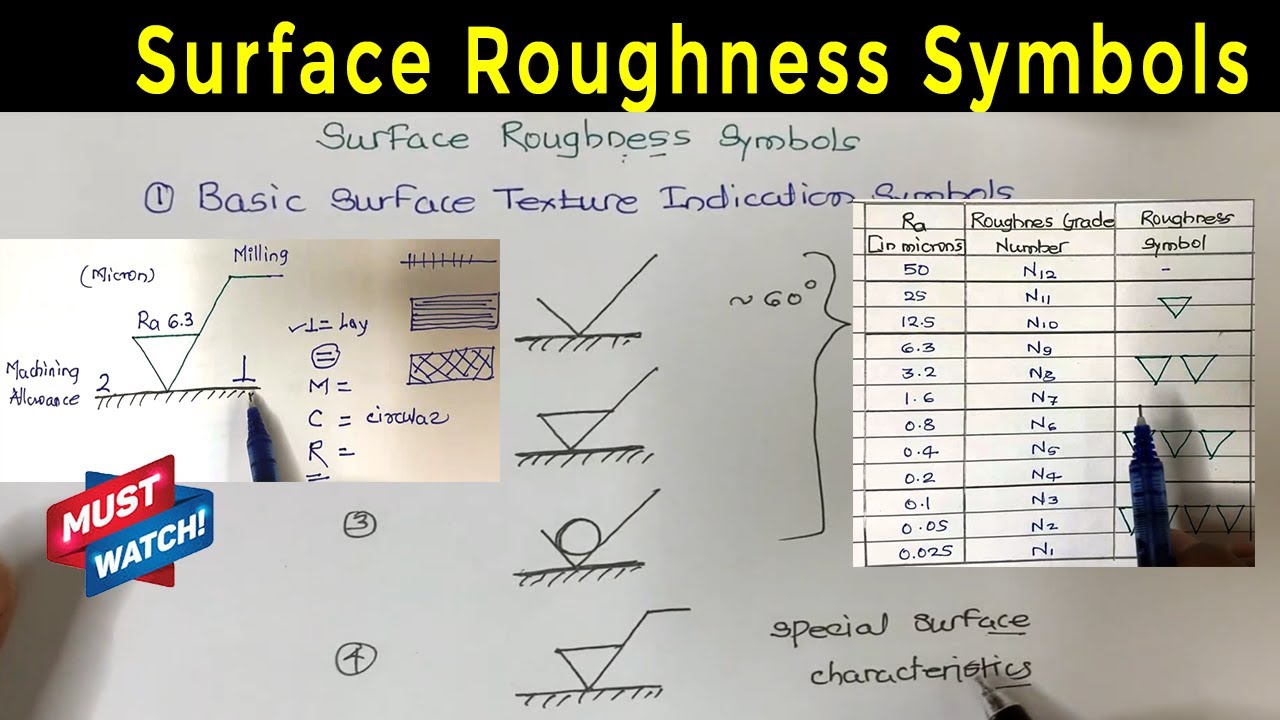

For machining processes such as milling turning and grinding factors such as cutting tool selection machine tool condition toolpath parameters feeds speeds tool deflection cut width stepover cut depth coolant and vibration are just a. The surface roughness is the measure of the total spaced irregularities on the surface. Here is a table showing maximum and minimum Ra values can produced on each production methods.

So in order to achieve the high grade finish ie. It is a measure of the complete texture of a products surface that is defined by three characteristics of surface roughness waviness and lay. Answer 1 of 3.

Which one of the following conventional machining processes is closest to grinding bmilling. Since surface finish is a fairly stable condition and can be predictable in that when the materials cutting. This process is mainly used in machined aluminum parts.

An as-milled finish is most suitable for prototypes and jigs and fixtures. You can buy a flat block like the one above which you can use as a comparison to see what surface finish youre getting. The former helps reduce the Built-up Edge BUE that aids to a prolonged tool life whereas the latter is to prolong insert life.

The section above is for CNC Turning surface finishes. It involves an electrochemical process that provides additional protection on top of the natural oxide film present on aluminum alloys such as 6061 and 7075. Surface finish is a parameter that determines the physical characteristics appearance of a component.

It is a means of altering material surfaces through processes involving adding removing or reshaping the metal surface. For machining processes such as milling turning and grinding factors such as cutting tool selection machine tool condition toolpath parameters feeds speeds tool deflection cut width stepover cut depth coolant and vibration are just a few of the many. Aside from protection this extra layer is excellent for insulation decoration and abrasion resistance.

Grinding abrasive cutting Polishing. Lapping is basically an abrasive process in which loose abrasives function as cutting points finding momentary support from the laps. Therefore it is the most cost-effective machining surface finish solution available.

A true or b false. Less than 62 Ra you can use the following processes. As such it has been monitored for just such a purpose.

Hi The term high grade machining refers to the surface finishes less than 62 Ra if am right. A 45 degree face mill produces a much nicer finish than a 90 degree square shoulder face mill. 33 rows Surface Roughness Produced by Different Manufacturing Process.

Use Chip Breakers Controlling the chips is the key to get a good surface finishThe chips produced are very much responsible for. Which one of the following abrasive processes achieves the best surface finish d superfinishing. There exist larger number of processes to fulfil the basic requirement of machining.

Surface finish refers to the process of altering a metals surface that involves removing adding or reshaping. For determining the most optimal surface finish the injection molder and the design engineer need to communicate. If something in the machining process is about to go haywire surface finish is one of the first places in the process that will reflect the change.

The surface finish options depend a great deal on the chemical make-up of the material being used and the design aspects of the part being manufactured. There are many factors that affect surface finish with the biggest being the manufacturing process see table above. Which of the following will improve surface finish in grinding a denser wheel structure b higher wheel speed g lower workspeed.

Without smoothing or polishing an as-milled standard machining surface finish should not incur any additional production costs. There are many factors that affect surface finish with the biggest being the manufacturing process see table above. Surface finish has historically been an indicator of process stability.

So you can already see that 125 is like a plowed field and. Use Sharp Inserts Lead Angle and Positive Rake. Material removal in lapping usually ranges from 003 to 03 mm but many reach 008 to 01 mm in certain cases.

True EXTRA - Surface technology is concerned with 1 defining the characteristics of a surface 2 surface texture 3 surface integrity and 4 the relationship between manufacturing processes and the characteristics of the resulting surface. How the molding process affects the surface finish. The choice of material.

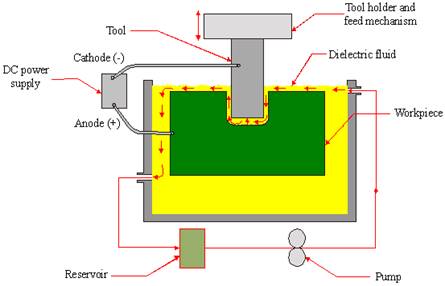

All things considered sharper inserts more lead angle and positive rake all lead to better surface finish. Electrical discharge machining EDM Milling.

What Exactly Is Machining Popular Types Tools Techniques Condor Machinery

Unconventional Machining Process Magnetorheological Fluid Based Surface Finishing

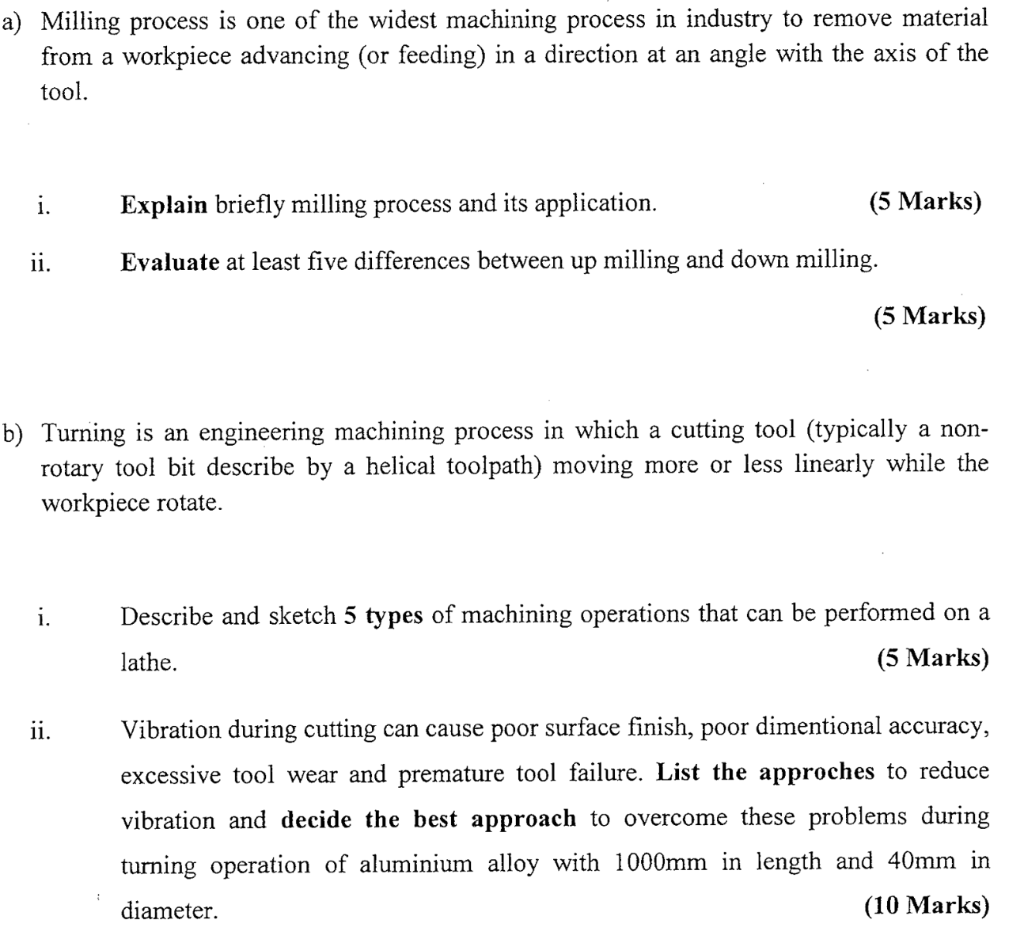

Solved A Milling Process Is One Of The Widest Machining Chegg Com

All About The Metal Machining Process Surface Finishes And Tolerances Videos Qualityinspection Org

Surface Finishing Basics Fractory

Select The Machining Process Which Gives Best Surface Finish

Non Traditional Manufacturing Processes

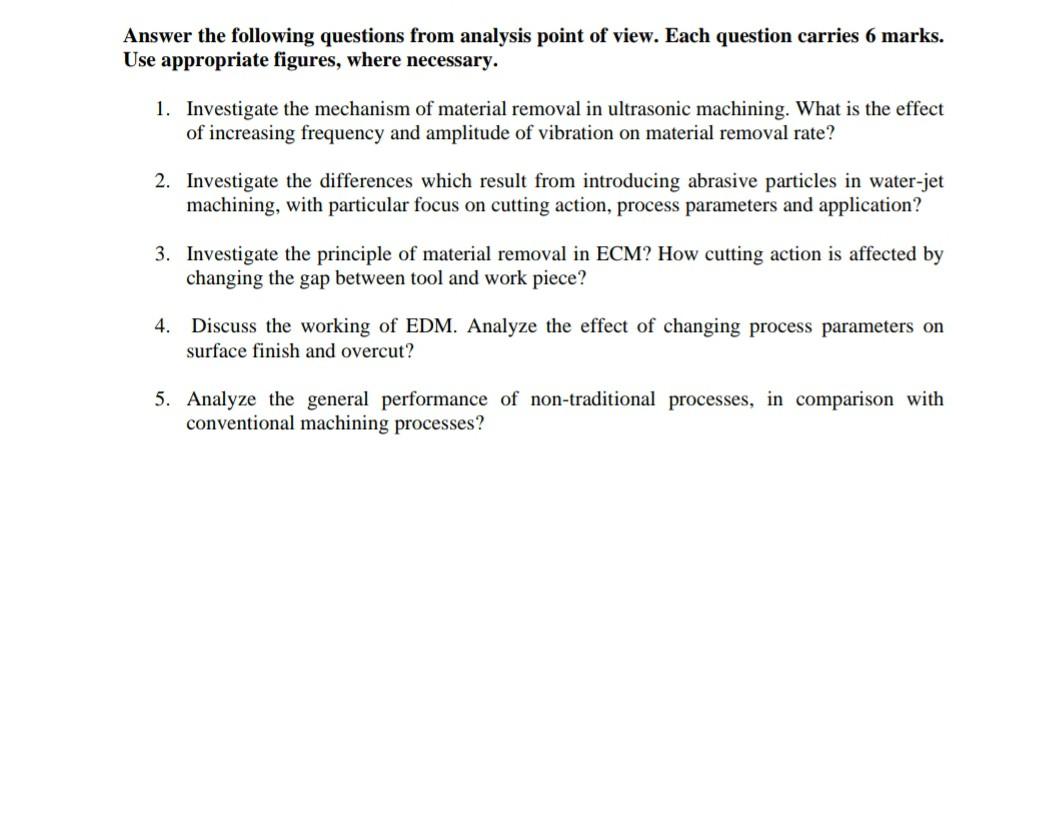

Solved Answer The Following Questions From Analysis Point Of Chegg Com

Classification Of Non Traditional Machining Processes 8 Download Scientific Diagram

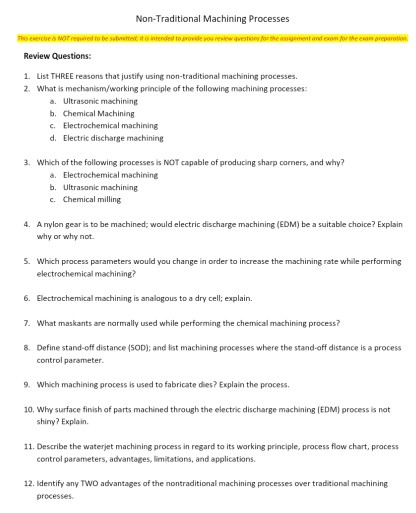

Solved Non Traditional Machining Processes Review Questions Chegg Com

Surface Finish Effects On Sealing Performance Eclipse Engineering Inc

Complete Surface Finish Chart Symbols Roughness Conversion Tables

Manufacturing Project Supplemental Material

Difference Between Roughing And Finishing In Machining

Surface Roughness Chart Understanding Surface Finishes Rapiddirect

Solved Question 2 25 Marks A Identify The Parameters Of A Chegg Com

How To Choose The Right Surface Finish For Machined Aluminum

Classification Of Machining Processes Download Scientific Diagram

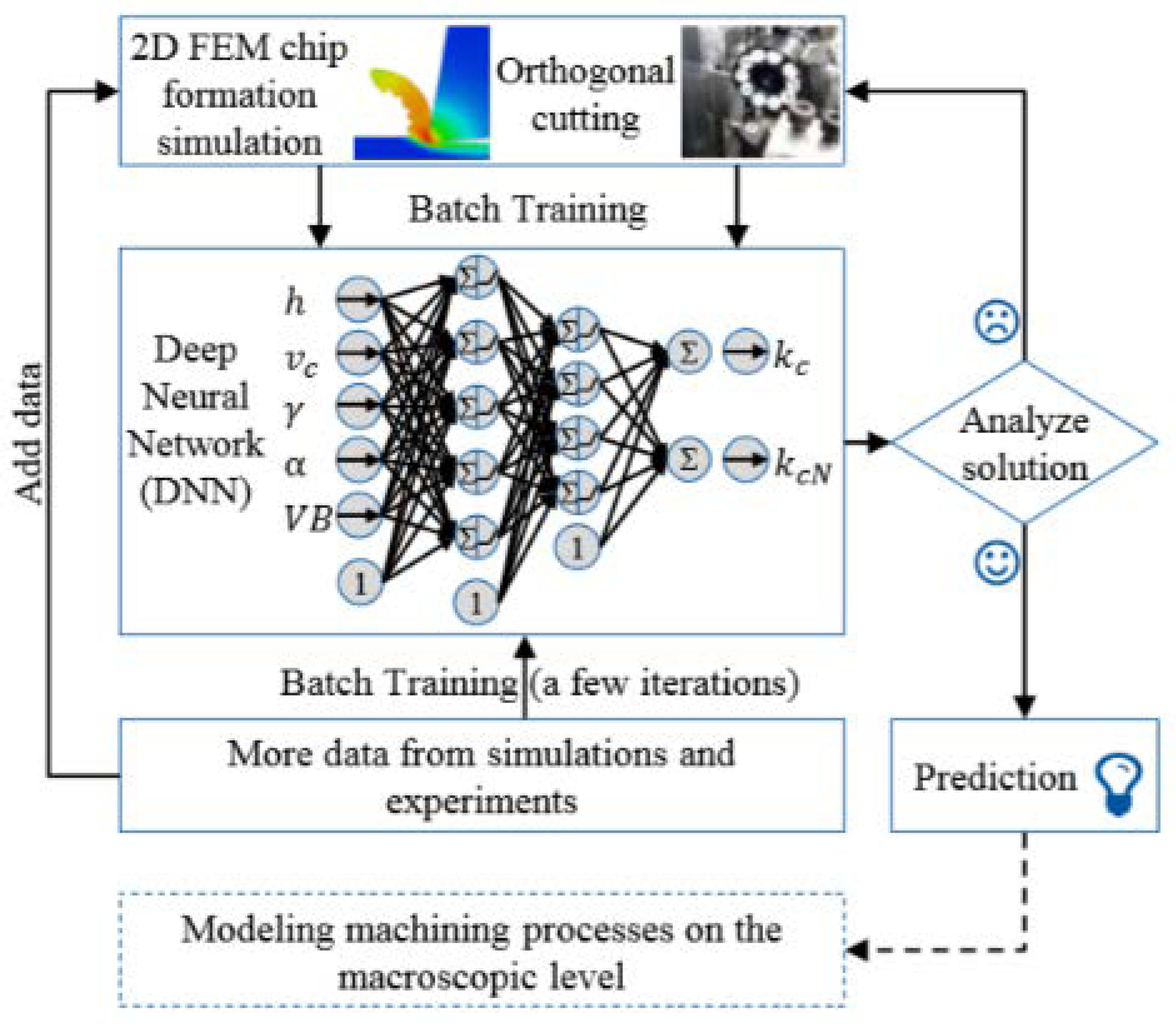

Sensors Free Full Text Cutting Forces Assessment In Cnc Machining Processes A Critical Review Html

Comments

Post a Comment